Unfortunately, we have been obliged to deal with an ever growing defects list since the first day we set foot onboard our Princess 55. This is yesterday's news.

What is today's news is that Princess started to follow their own agenda, progressively ignoring our requests. Just check out the "List of issues" on our main page and their status to see what we mean. Just to be clear, we're updating all of these posts on an almost daily basis, so items highlighted in red are indeed still pending.

Traveling for business: Our boat left unattended

We had to leave our boat last week and gave advance notice to Princess about urgent problems (affecting the functionality of the boat) that needed to be fixed. We asked them to not handle some of the mainly cosmetic issues because they required dismantling, painting, grinding, sanding etc therefore were messy in nature. Because nobody from us will be onboard and we have previously witnessed how clean(!) and well organized(!) and systematic(!) and closely supervised(!) their technicians worked (Check out

this post), we have decided to leave out these items to be fixed at a later date. We have specifically asked Princess to closely supervise all works and not to let junior technicians work onboard unattended.

Fix the easy stuff, procrastinate others

This should not come as a surprises as easy items are fixed in minutes and are each worth one tick on a checkbox, just like the complicated ones. So why not get the easy ones done first and give more time to ponder about the others?

Whilst this reasoning might make sense from a dealer's viewpoint, it certainly works the other way around from the owner's viewpoint. This is when we end up seeing scratches polished, seals replaced, rusty spots cleaned whilst the engine room and lazarette is baking from heat because extractors are down, aircon system is not cooling, bilge is flooding with fresh water. Not to mention the lifeline netting which is still not in place after 6+ months! (check out

this post)

They love to work on unoccupied boats

Not because it restricts their access (this is the version you will usually hear from them), but more like it restricts their freedom.

When nobody's onboard, they could treat your boat the way it pleases them as opposed to the way it pleases you, they don't have to answer your questions, they don't have to deal with your rules, they don't have to show up at a certain day/time, and most importantly, nobody will be there to check if the problem indeed has been properly fixed or not.

Aircon system left on for the weekend... "To test"?

Let's first answer the question "How do we know?"

Last week before we left, we placed a few motion activated wireless security cameras onboard. These systems are quite popular and effective nowadays and besides their usefulness for security purposes, cameras come also handy in that it lets us keep an eye on who entered/exited our boat, and if pointed towards the main electrical panel, allows us to check the status of the boat systems, indicators, voltages, amps, switches etc.

|

| Before leaving, we bluetaped breakers that needed to be left on at all times. A camera that was pointed in this direction also let us see voltages, amps, status indicators, breaker positions etc... |

On Friday evening, as we were checking motion footage recorded by our cameras on our cloud account, we have seen that the air conditioning subcontractor came onboard in the afternoon to fix the problems that we have previously reported (poor cooling performance in Saloon, guest cabin aircon unit not working - Check out

this post).

We noticed that the aircon subcontractor turned on all of the aircon units at around 15:05 to check their performance, make some measurements and finally left the boat at around 16:50 leaving ALL of the aircon units ON.

Two junior Princess technicians worked onboard until later the same evening and left at 20:52. We thought and hoped that they would take an extra minute to check all areas before leaving the boat and turn off aircon systems. Unfortunately did not happen. They just rushed out of the boat without checking or turning off anything at all.

Our messages were ignored

We immediately sent an email message to Princess service manager and to his assistant at 21:18 asking them to go back onboard and turn off all systems. To be honest, we were sure as hell that our email was going to be ignored, but still wanted to go on record with this one. After sending our notice, we arranged a personal contact to go onboard and turn off the aircon system. Since Princess had the keys to the boat and the main entrance door was locked, we have told our contact which breakers to flip off in the Engine Room AC panel. He went onboard towards midnight and turned off the system.

Princess never replied to our message and never took any action.

A well known cliché amongst service technicians for stuff they forget to switch off is "left on to test". If Princess decide to reply to our email, we are pretty sure that this would be their answer as they have nothing else to say.

What's the big deal if the Aircon is left on?

If the boat was attended, probably we would not care as much. But since the boat was going to be unattended during a full weekend (3 nights), anything could happen from flooding due to a cracked or damaged seawater pump pipe/hose to even a fire due to an electrical issue (especially considering the built quality of the boat!), which could very well have ruined other boats in the marina as well, particularly considering that our berth is only a few meters away from the fuel station!

If one assumes that in any case our boat insurance would cover all damages, he or she should think carefully. There is no way on earth that this clear act of negligence would be covered by insurance.

Let alone the lack of professionalism and proper supervision, we found this to be a good example of a reckless human behavior too.

All show an no go?

When we have specifically asked for all works to be supervised by a qualified engineer (based on our previous experiences), we have been told by Princess service manager that the person who would supervise the works was going to be on holiday. We then informed Princess that we would be happy to wait for him to come back and that we do not want any work to be performed without proper supervision. The answer was a mumbling "okay no problem" but we are now experienced enough to realize that at Princess, this tone could have a different meaning like "Don't hold your breath!"

Princess' access onboard has been revoked

Sadly, having witnessed this act of negligence and recklessness, we had no choice but to revoke access of Princess technicians and subcontractors onboard until one of us will be there to supervise them. Here is a copy of the email message that we have sent:

TO WHOM IT MAY CONCERN

It has come to our attention that on Friday 13.07.2018, Princess Motor Yacht Sales technicians and subcontractors attended M/Y.......... for repairs at .......... -without any supervision despite our previous notices- and knowing that the boat is/will be unoccupied for a period of time, left various ship systems -likely to fail and cause hazard if operated unattended- running as they left the boat for the weekend.

This negligent act jeopardized our boat's safety and put her and other neighboring boats under undue risk.

.......... sent an email message to Princess Motor Yacht Sales service supervisors/managers .......... and .......... same day at 21:18 asking them to rectify the situation immediately. Seemingly this message has been ignored. Not being able to reach PMYS technicians/supervisors in regards to this urgent matter, we had to use our own means to attend the boat at night-time and turn off above mentioned systems.

In light of the above and considering various safety and liability issues as well as insurance risks involved, as of immediate effect, we are hereby asking you to halt all works onboard and refrain from accessing M/Y ..........

We will be giving you advance notice when our crew is planned to be back onboard in order for you to arrange attendance to resume remaining repair works under proper supervision.

Kind regards,

Other email messages that we have never received replies to:

(1) To Service Manager

In regards to the lazarette ventilation system you have indicated that a team from UK will be flown in to handle the issue. Our previous experience with junior technicians from UK were not so favorable in terms of their experience and orderliness which unfortunately resulted in other issues including new damages.

May I ask why a crew from UK will be flown in whereas .....'s experience and skill sets are more than adequate to handle this job?

. . . In the meantime, you may schedule repair works to start on 12th of July at 12:00. The boat will be accessible (you have the keys) but unattended until the 19th of July.

Please, proper protection to be put in place before any work is performed and all works to be supervised at all times by a qualified engineer.

(2) To Service Manager

Please find updated pending items list attached.

My notes regarding schedule/timing on rightmost column.

(3) To Service Manager

Just to remind you that the boat is accessible for repair works since yesterday (12.07).

....... had main entrance door keys.

Passerelle retracted but boat accessible from stbd.

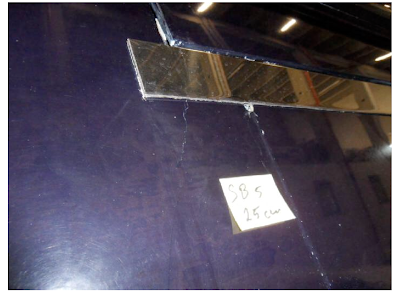

Main panel switches to stay on at all times bluetaped (see attached).

Before leaving, I noticed that center bilges (companionway + master cabin) contained fresh water (around 30-40L - see attached). Emptied partly via bilge pump. Please have your techs check master cabin shower (possibly a leak from shower mixer or hose connections) and clean/dry all bilges.

(4) To Service Manager

May I kindly ask you to call your tech team and have them go back onboard to turn off Master cabin aircon system (and check/turn off other cabin aircon systems) as they have no reason to run all weekend. Many thanks in advance.

16 July 2018 - Update

As we were thinking that Princess had to send some kind of reply to our revocation letter, their answer hit our inbox.

Here is what they wrote with our notes/comments in

bold letters

Thank you for your e mail below the contents of which are noted, but we take the opportunity to correct some of your assertions in this e mail.

PMYS had express permission to attend the craft and perform unsupervised (Really? "Unsupervised?". See underlined section below) from 12th July at 12:00 - see the copy of e mail below:

From: ..... (Owner's rep)

Sent: 09 July 2018 10:37

To: .... (Service Manager)

Subject: Re: ..... (Boat name)

Good morning ...,

Many thanks for this.

Just to let you know that I am only authorized to comment in regards to contents relating to technical aspects and availability of the boat. Your worksheet contains other information (ie in header) subject to ongoing discussion/disagreement. (At every opportunity, Princess is trying to insert wording in their communication to imply our acceptance of the boat. Each time we have to answer with a disclaimer)

In regards to the lazarette ventilation system you have indicated that a team from UK will be flown in to handle the issue. Our previous experience with junior technicians from UK were not so favorable in terms of their experience and orderliness which unfortunately resulted in other issues including new damages.

May I ask why a crew from UK will be flown in whereas ......'s experience and skill sets are more than adequate to handle this job? (Never received an answer to this but the reason is most probably cost: Junior technician flying in from Plymouth is on Princess payroll, whereas local high skill engineer works on freelance basis)

. . . In the meantime, you may schedule repair works to start on 12th of July at 12:00. The boat will be accessible (you have the keys) but unattended until the 19th of July.

Please, proper protection to be put in place before any work is performed and all works to be supervised at all times by a qualified engineer. (Notice this underlined phrase where we specifically used the word "supervised". Interesting to see that Princess read it as "unsupervised"!)

The air conditioning was being repaired on Friday 13th July and was expressly left on by the Dometic dealer’s engineer in order to test the system. (There it is, just as we have guessed...)

This is not a negligent act as you allege because air conditioning systems are designed to run day and night for the passengers’ comfort. (OK. But where were the passengers seeking comfort? What is it that the dealer was checking by leaving the system on for 3 consecutive days and nights? In an unattended boat, who would have known/observed if the system did or did not function properly? And most importantly, who would have intervened in case of a problem?)

There was certainly no danger to the craft or anyone else.

It is again incorrect to suggest we ignored the message sent by ...... The message was sent to ...... (Our contact, who tried to reach Princess technicians to get hold of the door keys in order to access the boat. But as nobody answered his calls or replied to our emails, we told him to switch off the aircon breakers from the engine room) at 21.10 who attended the craft and switched off the air conditioning at 22.15pm.

Therefore you are mistaken in this regard. (As usual!)