On her first season, apparently the captain noticed that the boat was cracking from various locations on the hull and superstructure and immediately ordered a survey. According to this survey report, the boat was a 1 year old 30m Princess with more than 60 cracks ranging from a couple of centimeters to more than a meter on some locations.

The owner hired a surveyor to investigate the cause of the cracks.

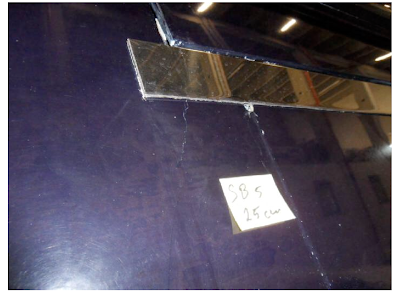

Below, quoting some parts and attaching some pictures from the very survey report that we bumped into during our research:

"The yacht was placed in a cradle on land in an indoor winter storage and was accessible and free to survey from all sides. The inspection was done visually and focused on anomalous cracks in the surface. Found cracks were marked and numbered and documented in the following report. Normal scratches, obviously caused by normal usage of the yacht were not considered nor documented."

"The concentration of hull cracks around 7m from the transom and 14m from the bow are close to the sling lifting positions. The sling lifting plan of the builder shipyard showed a forward double sling and an aft double sling position."

"Consequently the engine room and propulsion layout of ..... concentrate all the weight in the aft area of the hull. When placing the aft slings under the forward engine room bulkhead without any further sling support under the engine room during a lifting process, the aft part of the hull will bend down. It is to assume that the regular bending of the hull might be visible in form of cracks on a thick faired surface."

"According to the plan, the forward lifting point leaves around 14,5m of the forward hull unsupported. It is to assume that the location of the cracks in correspondence with the lifting slings and with the long unsupported forward hull stay in correlation."

"The inspection of the hull showed that the hull deck joint is covered with a stainless steel rub rail. Above the stainless steel rail various smaller horizontal cracks could be identified. These cracks were randomly spread over the whole yacht. On the inner side of the bulwark most of the cracks could be detected in the round edges of the freeing ports. Additional cracks could be found on all bulwark doors. Cracks on various places on the bulwark doors showed mostly that the door inlays to support the screws of the door hinges were damaged. Cracks were found around hinges and on some doors a visible damage on the surfaces could be made out that indicates that the inlays in the door is split or broken and pushed the laminate to the side. This might also occur when a wooden inlay is chosen, water comes through cracks and the wood expands. This might either be cause of a not proper installation or already a secondary damage."

"The general GRP material flexibility is interrupted in areas where parts are glued together. The horizontal cracks above the stainless steel rub rail show stress in the area of the hull-deck-connection. The gelcoat cracked around the stiff areas where flexibility exists. These cracks could have occurred when the boat bended or even already during the installation process of the deck on the hull when the deck was screwed down to the hull flange."

"Cracks on freeing ports in general can occur when stress and pressure is on the bulwark and both outer side and inner surface of the bulwark have movement in different direction. This could happen during the production process if the deck is not perfectly fitted on placed bulkheads or if the deck is forced down to the hull flange connection."

"Within the inspection of the superstructure various randomly located cracks were found. Especially on the starboard side two bigger cracks were detected with a parallel vertical direction in a distance of 40cm to each other which might be also caused by movement or bending of the superstructure."

"In the summary it can be said that hull, as well as deck and superstructure, are affected by cracks. The location and concentration of hull cracks close to prescribed sling positions in correspondence with the unsupported weight of the forward and aft section by lifting process suggest the assumption that the cracks were most probably caused through lifting processes since they exert most pressure and stress on the boat structure. The same applies to the cracks in the bulwark and the superstructure that showed in general various minor cracks. Regarding the cracks in the doors it can be assumed that the internal structure of the doors is not properly to support the hinges and the weight of the doors."

"In order to avoid future cracks in the hull the thickness of the existing filler needs to be reduced which should be done by sandblasting the yacht to remove the existing filler. The hull laminate should be laid bare and in deep areas laminate should be added to make the hull surface smooth as possible. The hull needs to be re-faired with a strong filler with an internal stiffness and that is flexible enough to not break and strong enough to resist a bending of the yacht. The fairing process as such needs to be done the way that the existing filler is primarily sanded down to the highest lamination points instead of just adding new filler on top. Afterwards filler can be applied step by step to reach a smooth surface. Just adding filler is a common and easy method but not recommended. Cracks around the rub rail and on the bulwark surface should be treated the same way. Freeing ports need to be sanded completely down to the laminate and the cracks should be opened and then re-laminated. Additional layers of laminate in the freeing ports should avoid future cracks. The bulwark doors should be rebuilt completely. The focus should be to build the doors as light as possible. The inlays for the hinge fixation should be made of aluminum or stainless steel with an internal grid in order to support the weight of the doors on different points. The internal structure of the doors should carry the open/close mechanism. The outer GRP shell should function as shell only. The cracks on the superstructure need to be largely opened and afterwards supported by additional lamination. Furthermore the sling lifting plan should be revised and a focus should be on the internal weight distribution. The lifting plan needs to be redesigned according to the weight positions in connection with the inner structural elements such as transversal frames, longitudinal stringers and bulkheads. The focus of the works to be carried out should ensure that the bending of the boat is reduced during a lifting process by slings."